NOV Brandt ATL 1000 Composite Shale Shaker Screen – API RP 13C Replacement

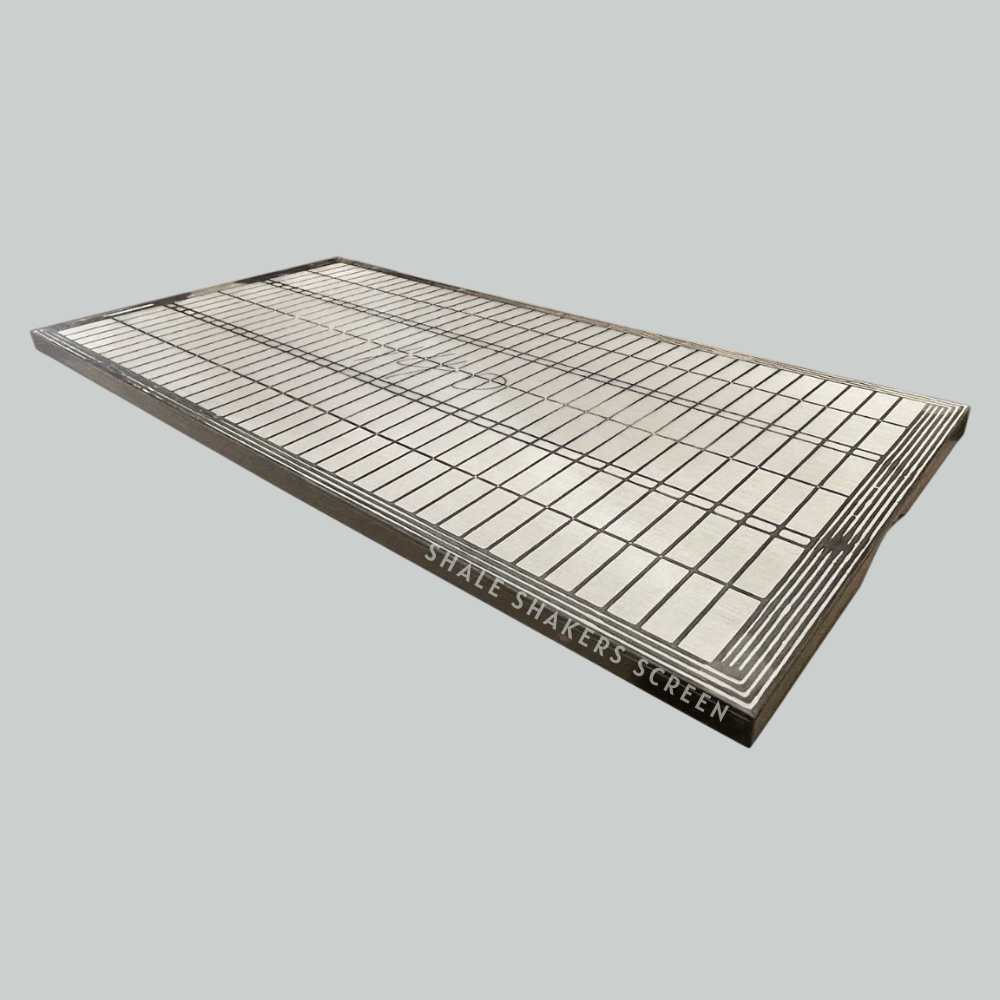

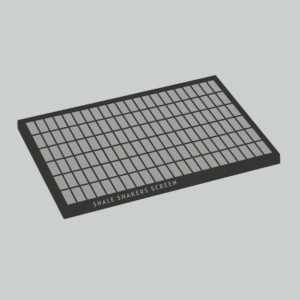

Aftermarket composite shale shaker screens for NOV Brandt ATL 1000™ shakers. Built with multi-layer stainless steel mesh (SS304/SS316) and strong composite frames, these screens are API RP 13C compliant and available in API 10–325 mesh sizes. Designed for high fluid handling capacity and extended screen life, supplied worldwide by a trusted shale shaker screen manufacturer.

Description

ATL 1000 Replacement Shaker Screens for Oilfield Drilling

Our NOV Brandt ATL 1000 composite shaker screens are engineered for high-volume drilling mud solids control in global oilfield operations. Manufactured as aftermarket replacement screens, they deliver precise separation, higher conductance, and longer service life compared to conventional steel frame panels.

Features & Benefits of ATL 1000 Composite Screens

-

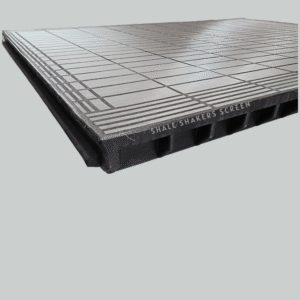

Composite frame construction – lightweight, rust-free, durable under high G-force.

-

Mesh range: API 10–325 (covering a full set of shale shaker screen API numbers).

-

Screen types: Flat (PWP), Pyramid (PMD), and corrugated 3D shaker screens.

-

API RP 13C tested – verified for D100 cut point, conductance, and non-blanked area.

-

Screen longevity: 400–450 hours average service life.

-

Dimensions: 25″ × 49.3″ (≈ 635 × 1252 mm).

-

Compatibility: NOV Brandt ATL 1000™, Cobra™, King Cobra™, and Venom™ shakers.

Technical Specifications

-

Frame: Composite aftermarket replacement.

-

Mesh Material: SS304 / SS316 stainless steel wire cloth.

-

Screen Styles: PWP (flat), Pyramid PMD, and wave/corrugated shaker screens.

-

Applications: Suitable for oilfield shale shakers, horizontal directional drilling (HDD), mining screens, and coal cleaning screens

Applications in Solids Control Systems

The ATL 1000 shaker screen is widely used for drilling mud screens in onshore rigs and offshore platforms. With higher flow rates and improved conductance, these solids control screens ensure efficient mud treatment, protect downstream equipment, and reduce fluid loss during drilling.

Disclaimer

NOV Brandt™, ATL 1000™, Cobra™, King Cobra™, and Venom™ are trademarks of National Oilwell Varco. The screens described here are aftermarket replacement products manufactured by Anping County GuangMing Metal Products Co., Ltd and are not OEM products. They are designed for compatibility only and tested according to API RP 13C standards.

Inquiries & Orders

Looking for ATL 1000 shaker screens for sale? Contact us today for bulk pricing, API RP 13C reports, and fast worldwide delivery from a leading shale shaker screen supplier.