NOV Brandt VSM 300 Scalping Composite Shale Shaker Screen – Replacement API RP 13C

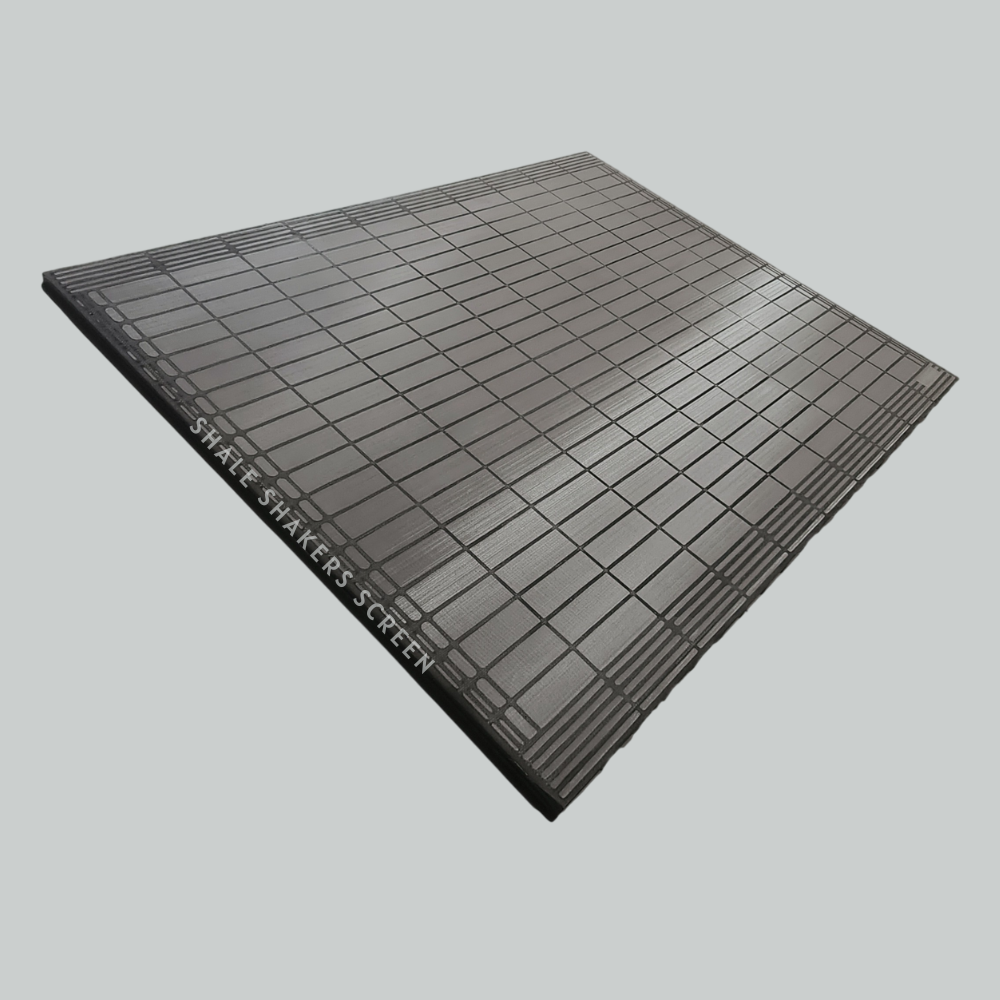

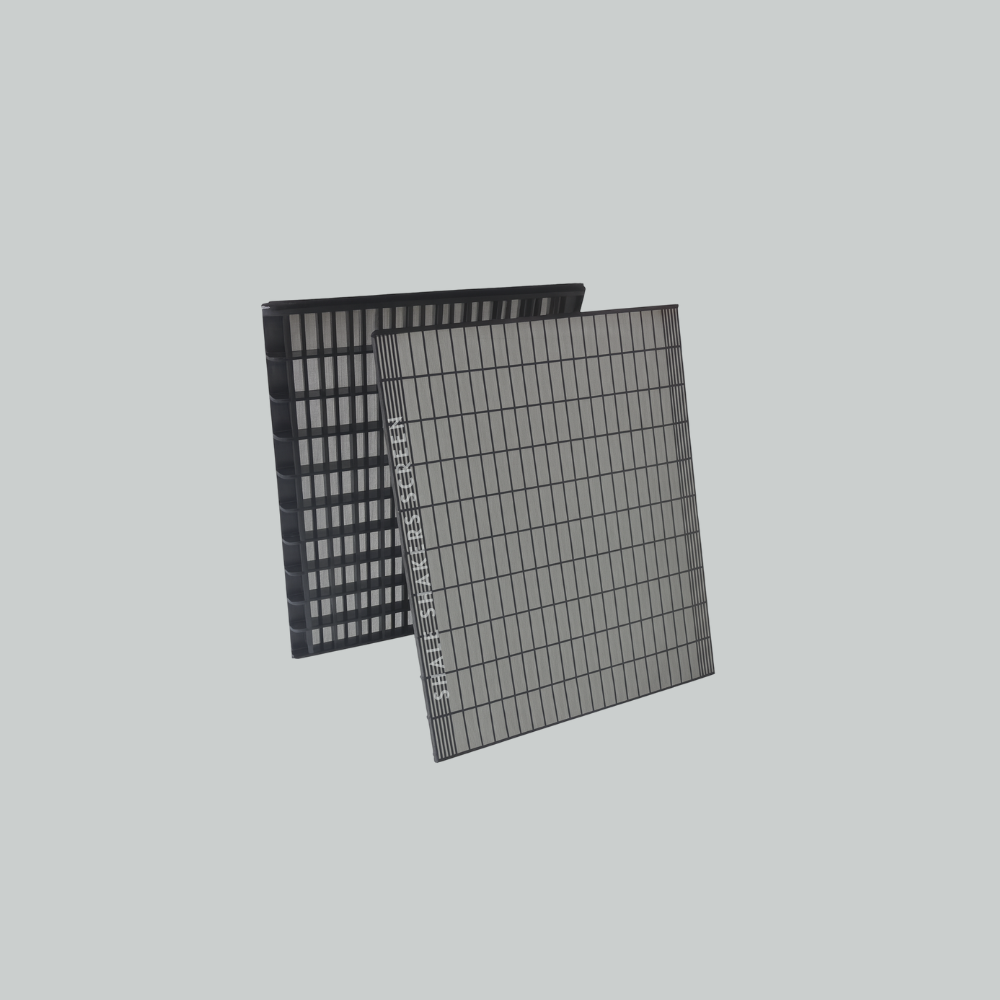

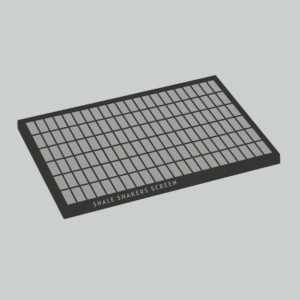

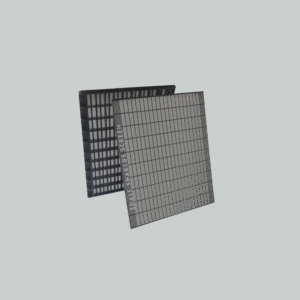

Premium replacement composite shaker screens for the NOV Brandt VSM 300™ Scalping Deck. The scalping screen is the first line of defense, removing large drilled cuttings before mud passes to the primary deck. Manufactured with composite frames + SS304/SS316 mesh, these aftermarket drilling mud screens are API RP 13C certified and available in API 10–325 mesh sizes.

Description

VSM 300 Scalping Deck Explained

The scalping deck screen is installed on the top deck of the NOV Brandt VSM 300 shaker. Its role is to remove large solids and cuttings before the mud reaches the primary screen.

-

Scalping = first separation stage (large particles).

-

Primary = main solids removal (bulk of mud volume).

-

Secondary/Drying = final recovery of drilling fluid.

Because it protects the lower decks, the scalping screen often uses coarser mesh sizes (API 10–60) and is critical for extending the life of the primary screen.

Features & Benefits of VSM 300 Scalping Screens

-

Composite frame design – corrosion-proof, lighter weight, longer service life.

-

Mesh sizes: API 10–325 (but most commonly API 20–60 for scalping duty).

-

Screen options: Flat PWP and Pyramid PMD pyramid shaker screens.

-

API RP 13C tested – certified cut point (D100), conductance, and non-blanked area.

-

Screen longevity: Typically 400+ hours depending on mud and solids loading.

-

Dimensions: ~26.6″ × 37.0″ (≈ 676 × 940 mm).

-

Compatibility: NOV Brandt VSM 300™ scalping deck.

Technical Specifications

-

Frame Type: Composite aftermarket replacement.

-

Mesh Material: SS304 / SS316 stainless steel wire cloth.

-

Construction: Multi-layer mesh bonded to composite frame.

-

Applications: Shale shaker screens for drilling rigs, HDD projects, mining, and coal cleaning operations.

Applications in Solids Control

The scalping deck screen is essential for protecting downstream equipment and extending the service life of primary shale shaker screens. By removing coarse cuttings early, these drilling mud screens improve overall efficiency of the VSM 300 solids control system.

Disclaimer

NOV Brandt™ and VSM 300™ are trademarks of National Oilwell Varco. The products offered are aftermarket replacement screens manufactured by Anping County GuangMing Metal Products Co., Ltd and are not OEM products. They are designed for compatibility only and tested according to API RP 13C standards.

Inquiries & Orders

Looking for VSM 300 scalping screens for sale? Contact us for API RP 13C test reports, bulk order pricing, and worldwide shipping. We are a trusted shale shaker screen supplier for oilfield and HDD projects.