NOV Brandt VSM300 Secondary / Drying Steel Frame Shale Shaker Screens – API RP 13C Replacement

High-quality aftermarket NOV Brandt VSM300 Secondary / Drying Steel Frame Shale Shaker Screens for the bottom deck. These drying screens recover drilling fluids and dry drilled solids before discharge. Built with steel frame + SS304/SS316 mesh, they are API RP 13C certified shale shaker screens that ensure accurate cut point, strong conductance, and long service life. Available in API 10–325 mesh sizes with worldwide supply.

Description

VSM300 Secondary / Drying Steel Frame Shale Shaker Screens Explained

In the NOV Brandt VSM300 shaker, the secondary screens (also called drying screens) are positioned on the bottom deck. Their role differs from scalping and primary shale shaker screens:

- Scalping screens (top deck): Remove large drilled cuttings.

- Primary screens (middle deck): Perform bulk solids removal.

- Secondary / Drying screens (bottom deck): Recover drilling fluid and dry solids for discharge.

This makes VSM300 secondary steel frame shale shaker screens essential in reducing fluid loss and improving solids control efficiency.

Features & Benefits of VSM300 Secondary / Drying Steel Frame Screens

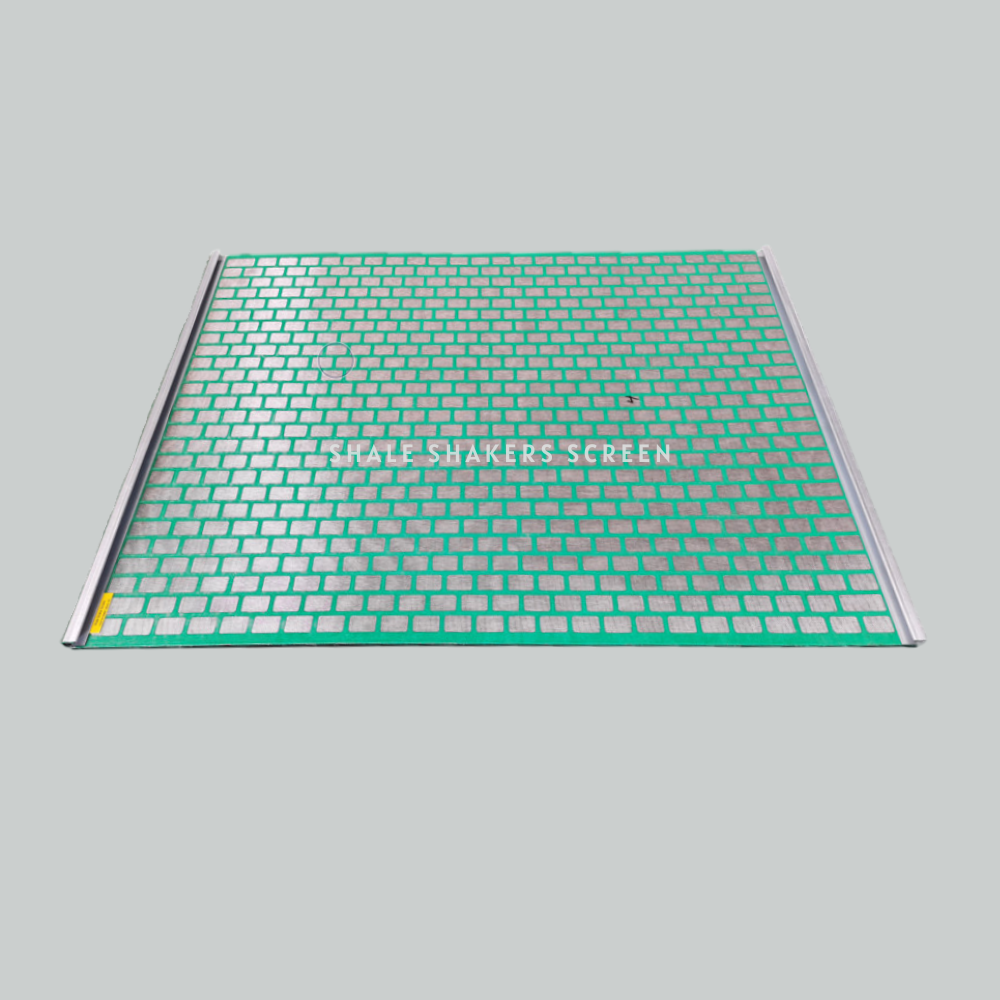

- Steel frame construction – strong, corrosion-resistant, long-lasting.

- Mesh range: API 10–325 (fine mesh for better fluid recovery).

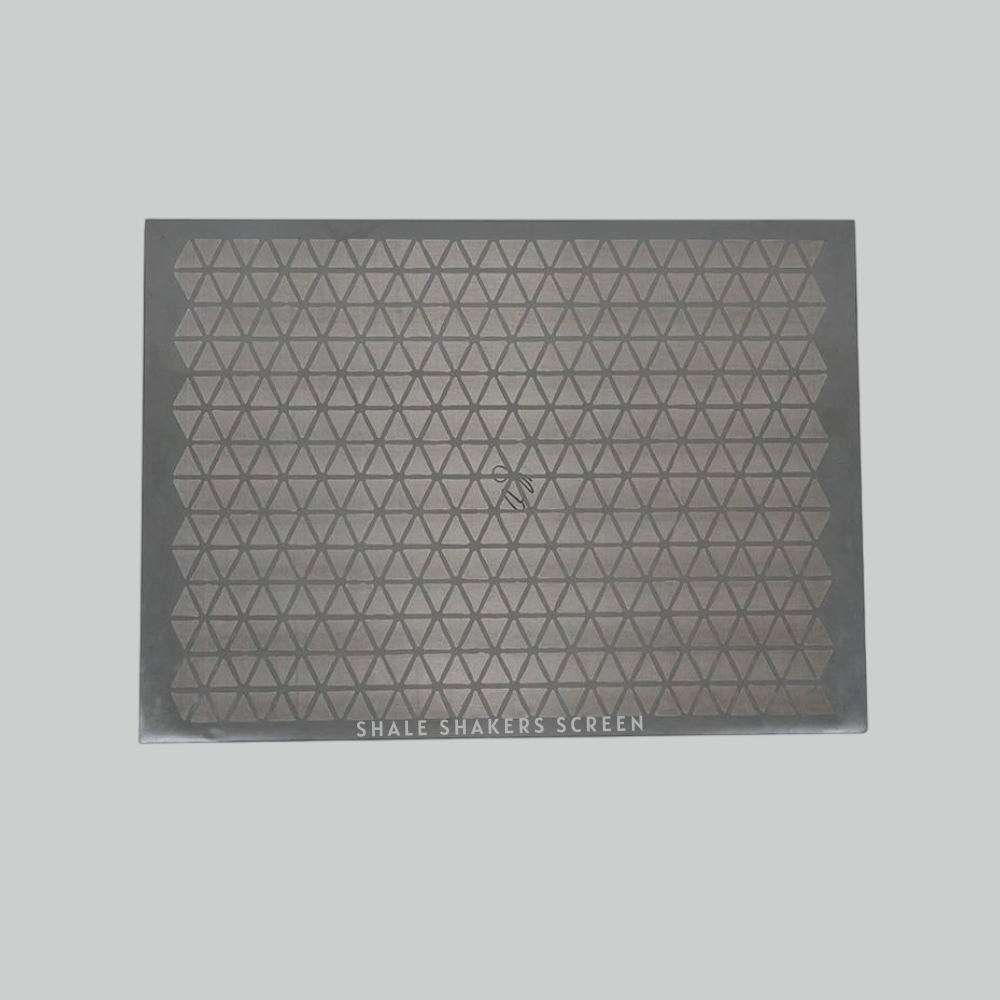

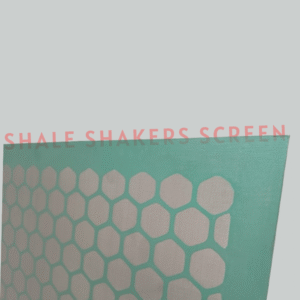

- Screen options: Flat PWP and Pyramid PMD shaker screens.

- API RP 13C tested – certified for cut point (D100), conductance, and non-blanked area.

- Working life: Average 400+ hours depending on drilling mud conditions.

- Dimensions: ~27″ × 8″ (≈ 686 × 203 mm).

- Compatibility: NOV Brandt VSM300™ secondary / drying deck.

Technical Specifications

- Frame Type: Steel Frame aftermarket replacement.

- Mesh Material: SS304 / SS316 stainless steel wire cloth.

- Styles: Flat PWP, Pyramid PMD, 3D corrugated screens.

- Applications: Steel frame shale shaker screens for oilfield drilling, HDD, mining, and coal cleaning operations.

Applications in Solids Control

The NOV Brandt VSM300 Secondary / Drying Steel Frame Shale Shaker Screens are critical for maximum fluid recovery and reduced waste. By improving separation efficiency and reducing drilling fluid loss, these secondary drying screens optimize the overall VSM300 solids control system performance.

Disclaimer

NOV®, Brandt®, VSM300™, and related names are trademarks or registered trademarks of National Oilwell Varco or its affiliates. The shaker screens described herein are aftermarket replacement products manufactured by Anping County GuangMing Metal Products Co., Ltd. These screens are not manufactured by, affiliated with, or endorsed by National Oilwell Varco. All referenced trademarks and model names are used solely for identification and compatibility purposes. Screens are independently tested in accordance with API RP 13C standards.

Inquiries & Orders

Looking for VSM300 secondary screens or VSM300 drying steel frame shale shaker screens? Contact us today for API RP 13C test reports, bulk order pricing, and global delivery. Trusted worldwide supplier of steel frame shale shaker screens for oilfield drilling and HDD projects.